Caractéristiques de conception structurelle des boulons à col carré à tête champignon Boulons à tête champignon en acier inoxydable à col carré sont...

EN SAVOIR PLUS

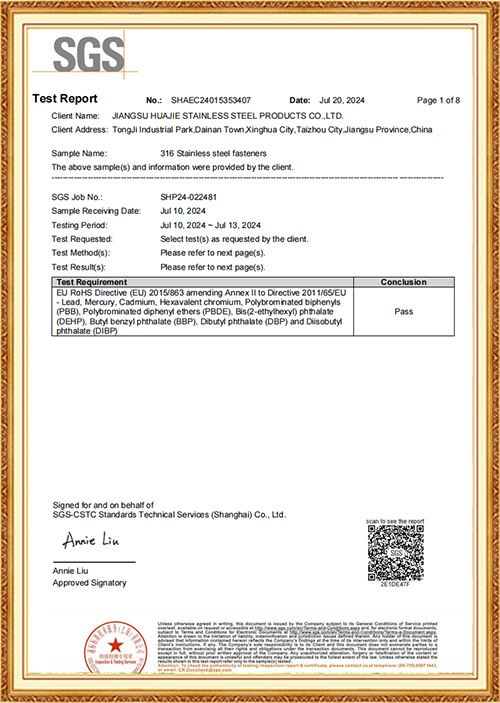

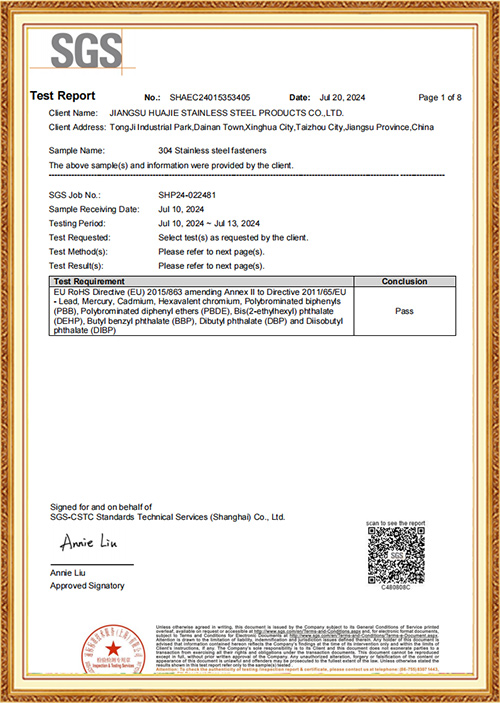

Notre société produit principalement des fixations en acier inoxydable. La société dispose d'équipements de production et de test avancés nationaux et étrangers, et les normes de produits couvrent les normes GB/JIS/DIN/ANSI/ISO, le matériau comprend 201/304/316L, etc.

-

-

Introduction à la haute résistance Vis en acier inoxydable Les vis en acier inoxydable à haute résistance sont des fixations essentielles pour les a...

EN SAVOIR PLUS -

Compréhension Tiges filetées en acier inoxydable Les tiges filetées en acier inoxydable sont des fixations polyvalentes utilisées dans diverses appl...

EN SAVOIR PLUS -

Résistance et durabilité de Vis à tête creuse à six pans creux Les vis à six pans creux sont largement reconnues dans les applications industrielles...

EN SAVOIR PLUS

Understanding Corrosion Resistance Coatings for Nuts: Why Stainless Steel Nuts Stand Out in Tough Environments

When it comes to selecting the right fasteners for long-term use, corrosion resistance is often one of the most critical performance factors. Nuts, as essential components in joint assemblies, are particularly vulnerable to environmental stressors such as moisture, chemicals, and extreme temperatures. That's why choosing the appropriate coating—or opting for corrosion-resistant materials like stainless steel nuts—can make a measurable difference in the lifespan and safety of mechanical connections.

Various coating technologies are used in the industry to combat corrosion, each with its own strengths depending on the application. Zinc plating, for instance, offers basic protection and is commonly used for indoor applications. However, it may not hold up well in outdoor or humid conditions. In contrast, hot-dip galvanizing creates a much thicker layer of zinc, offering improved protection for structural and marine uses. There are also more advanced treatments like PTFE and ceramic coatings, which provide not only corrosion resistance but also chemical shielding and reduced friction—ideal for high-performance environments.

Even with high-quality coatings, the core material of the nut still plays a vital role in determining overall corrosion resistance. That’s why stainless steel nuts are often the first choice for customers dealing with harsh industrial, marine, or outdoor conditions. Unlike carbon steel fasteners that rely heavily on surface treatments, stainless steel offers inherent corrosion resistance due to its chromium content, forming a passive layer that protects against rust and oxidation. This is especially valuable when coatings are worn away or exposed to extreme wear and tear over time.

But not all stainless steel is created equal. For example, A2-70 stainless steel nuts are widely used in general construction and food processing applications, offering solid resistance to most common forms of corrosion. Meanwhile, A4-80 variants, which contain molybdenum, provide even greater protection and are favored in chemical plants, coastal installations, and offshore engineering. The long-term savings in maintenance and replacement costs often justify the slightly higher initial investment in these specialized fasteners.

One point that is often overlooked is the compatibility of coatings and base materials within an assembly. Using stainless steel nuts with coated carbon steel bolts can sometimes lead to galvanic corrosion, especially in moist environments. This electrochemical reaction can accelerate the degradation of one of the materials. Industry best practices recommend matching materials where possible or using insulating washers to minimize such risks. These small choices can significantly impact the durability of a product in the field.

As a manufacturer with years of experience supplying stainless steel nuts to clients across sectors—from agriculture to aerospace—we understand how critical it is to match the right product to the right application. Customers often come to us not just for inventory, but for guidance on optimizing fastener performance under specific environmental demands. Whether you're looking for bulk quantities or specialized variants with custom coatings, we're here to help you make informed decisions that stand the test of time.

Corrosion resistance isn't just a technical specification—it's a long-term value factor. Investing in the right nut, whether through advanced coatings or material selection like stainless steel nuts, protects more than just hardware—it safeguards reliability, safety, and reputation.